Custom OEM Small Solar Panels (0.1W - 20W)

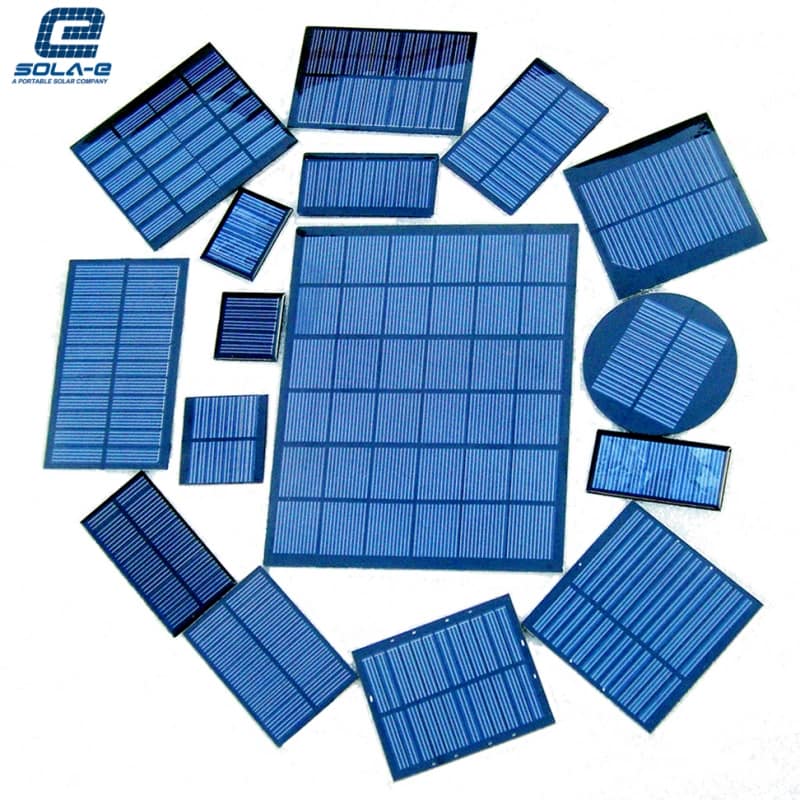

0.1W - 20W | Any Voltage | Any Shape

Choose Your Production Technology

We offer three main production technologies to match your application environment:

| Feature | Industrial Series (ETFE) | Consumer Series (PET / Epoxy) |

|---|---|---|

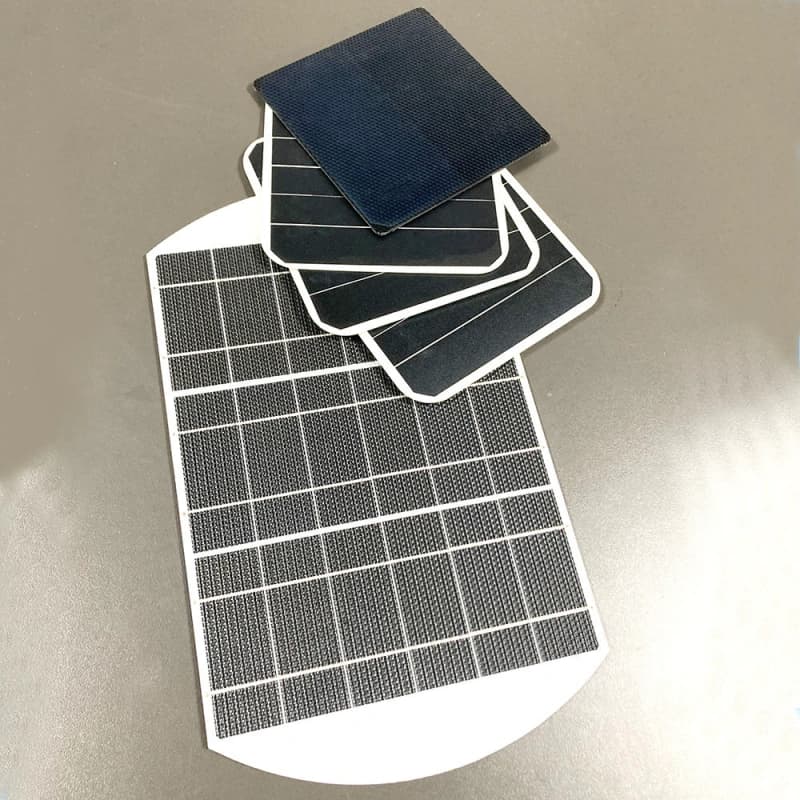

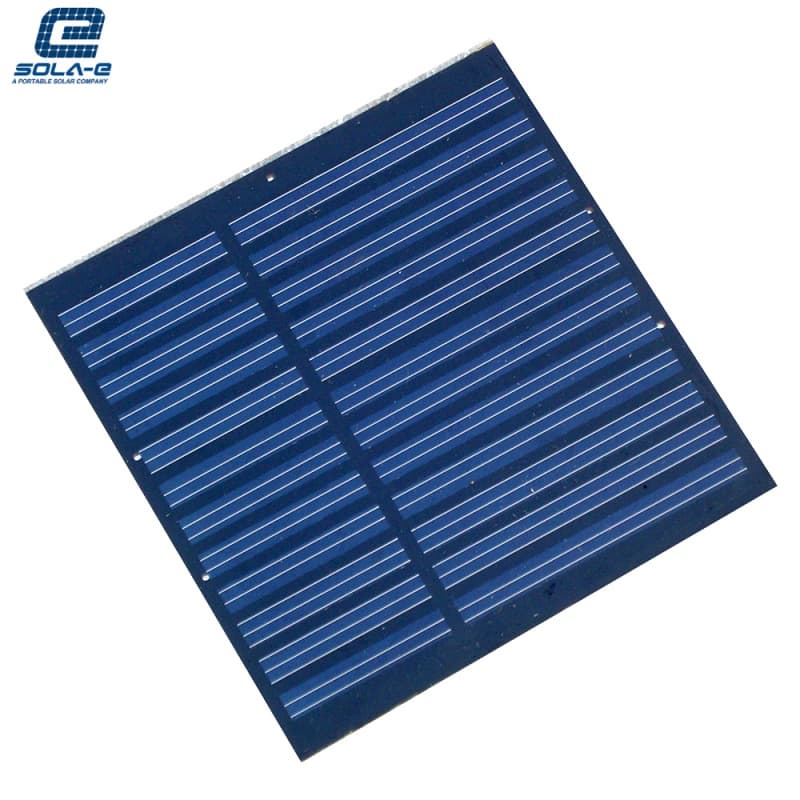

| Technology | ETFE Lamination | PET Lamination / Epoxy Resin |

| Manufacturing Process | High-Temp Vacuum Lamination (Cells fused with ETFE film under heat & pressure) | Glue Dropping (Epoxy) or Lamination (PET)(Liquid resin curing or standard thermal pressing) |

| Durability (Lifespan) | 5 - 7 Years (Marine Grade)(UV & Salt Resistant) | 1 - 3 Years (Standard)(Good for non-permanent outdoor use) |

| Surface Finish | Matte / Honeycomb Texture(Non-stick, self-cleaning) | High Gloss (Epoxy) or Matte (PET)(Crystal clear or smooth finish) |

| Key Benefit | Anti-Yellowing & Crack Resistant(Ideal for harsh environments) | Cost-Effective & High Aesthetics(Best balance of price and look) |

| Best Application | IoT Sensors, Marine Buoys, GPS | Solar Toys, Garden Lights, Education Kits |

| Action | Explore ETFE Modules | Explore PET/Epoxy Modules |

💡 Engineer’s Note: The Difference in Process

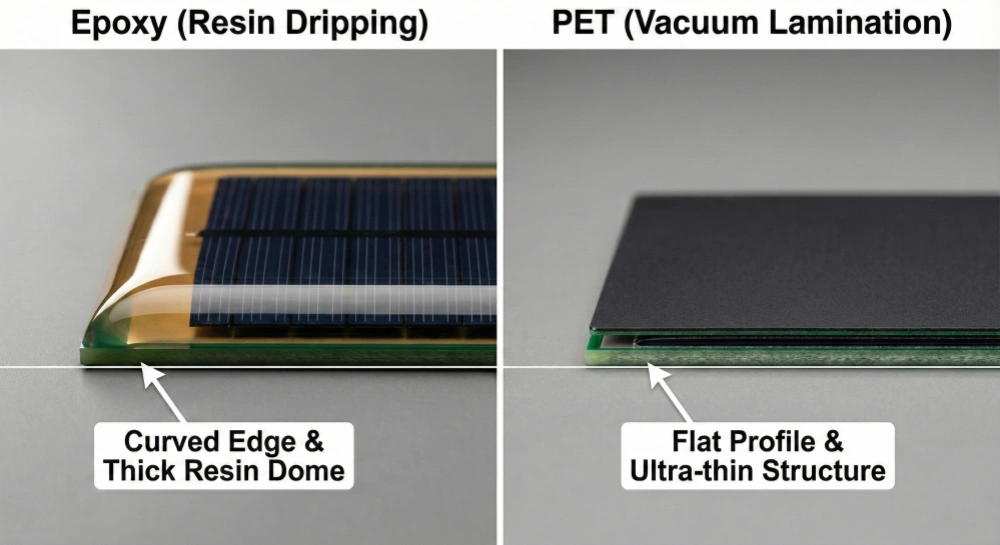

PET/ETFE (Lamination): Produced using a Vacuum Heat Laminator (similar to large roof panels). The materials are fused together under high pressure, creating a dense, flat structure that seals out moisture.

Epoxy (Dropping): Produced by manually dropping liquid A+B resin onto the cells. It naturally cures into a “domed” shape. While beautiful, the resin is chemically sensitive to UV rays, which causes the yellowing over time.

Unsure about Voltage or Material?

Don’t guess. Let our engineers recommend the best solution for your device.

Engineer's Guide - Battery & solar Matching

To ensure efficient charging, the solar panel’s operating voltage (Vmp) must be correctly matched to your battery’s nominal voltage. Please refer to our standard matching data below:

| Battery Chemistry | Battery Voltage Range | Required Solar Panel Voltage (Vmp) | Application Example | |

|---|---|---|---|---|

| Ni-MH & Ni-CD | 1.2V ~ 1.4V | > 2.0V (Min 1.8V) | Solar Lawn Lights, Toys | |

| LiFePO4 (LFP) | 3.2V ~ 3.65V | 5.0V (Min 4.0V) | IoT Sensors, Solar Street Lights | |

| Ternary Lithium (Li-ion) | 3.7V ~ 4.2V | 5.5V (Min 5.0V) | Power Banks, GPS Trackers, Cameras | |

| Lead Acid (6V) | 6V ~ 7.2V | 9.0V (Min 8.0V) | Emergency Lights, Gate Openers | |

| Lead Acid (12V) | 12V ~ 14.4V | 18.0V (Min 16.5V) | RV Trickle Charge, Marine Buoys |

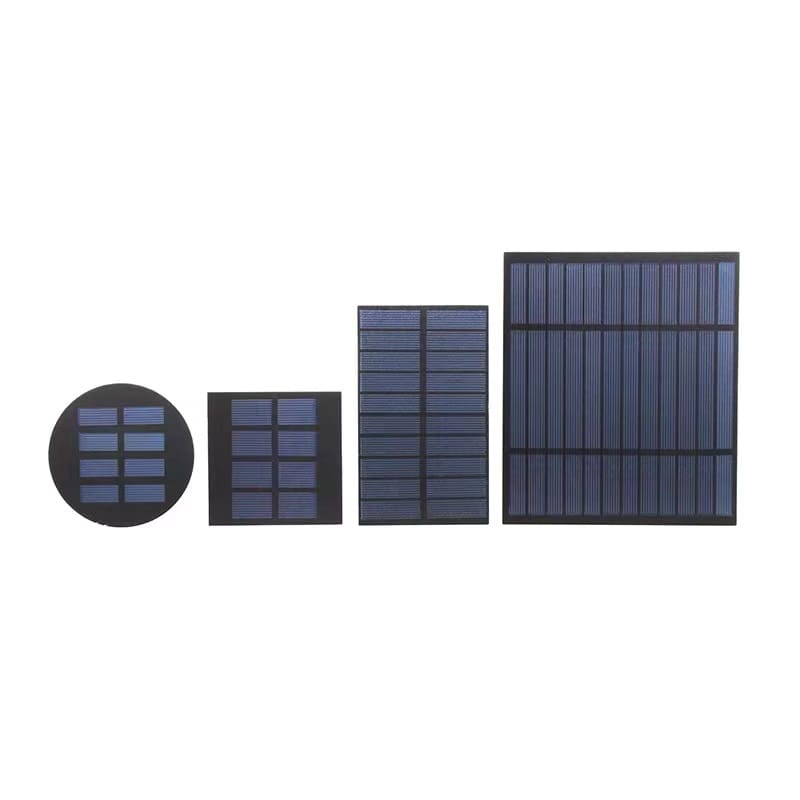

Use these standard dimensions to estimate the space required on your product housing.

| Target Power | Reference Dimensions (mm) | Matching Battery | |

|---|---|---|---|

| 0.5W | 70 x 50 mm | 1.2V Ni-MH | |

| 1.0W | 70 x 90 mm | 1.2V Ni-MH | |

| 2.0W | 90 x 160 mm | 3.2V LiFePO4 | |

| 3.0W | 100 x 160 mm | 3.7V Li-ion / 3.2V LFP | |

| 5.0W | 160 x 180 mm | 3.7V Li-ion / 6V Lead Acid | |

| 6.0W | 160 x 225 mm | 3.7V Li-ion | |

| 10W | 160 x 385 mm | 6V Lead Acid / 3.2V LFP | |

| 18W | 320 x 360 mm | 12V Lead Acid |

💡 Engineer’s Note:

Dimensions: The sizes above are for reference based on standard cell cutting. We can customize the Length x Width ratio (e.g., make it long and narrow) to fit your device perfectly.

Charging Current: Under the same light intensity and photovoltaic efficiency, larger panel area means higher current and faster charging.

Need precise dimensions for IoT integration? Get the full electrical & mechanical specifications here.

For OEM projects involving drawings, BOMs, or technical specifications, please contact our engineering team directly:

How to Customize Your Panel (4 Steps)

To provide an accurate proposal, please verify the following technical details with our engineers:

The solar panel voltage must be sufficiently higher than your battery’s voltage to charge it effectively.

Engineering Rule: Solar Vmp ≈ 1.5 x Battery Voltage.

Quick Match Table (Based on your datasheet):

| Battery Type | Nominal Voltage | Recommended Solar Panel Vmp | |

|---|---|---|---|

| Ni-MH/ Ni-CD | 1.2V | 2.0V - 2.5V | |

| LiFePO4 | 3.2V | 5.0V - 5.5V | |

| Li-ion/ Polymer | 3.7V | 5.5V - 6.0V | |

| Lead Acid | 6V / 12V | 9V / 18V |

Not sure? Just tell us your battery type, and we will calculate the cell number for you.

We maximize the active area on your device housing.

- Standard Shapes: Square / Rectangular (Most cost-effective, highest efficiency).

- Custom Shapes: Round, Triangle, or Arc shapes are available via precision laser cutting.

- Solar Cells: Choose Monocrystalline (21%+ eff) for the best performance in small sizes.

- Backboard Structure: We highly recommend FR4 (Fiberglass).

- Unlike paper or cardboard, FR4 is rigid, strong, and waterproof, making it safe to solder and easy to mount.

- MOQ: We support flexible MOQs for mass production.

- Samples: Sample Orders are available for prototyping and validation testing.

Why Choose Us

Why ETFE for Small Panels?

Small devices are often deployed in harsh environments. Our ETFE coating ensures the panel won't turn yellow or crack under sun exposure, guaranteeing 5+ years of reliable output for your IoT sensors or outdoor chargers.

Optimized 5V Output

Specifically engineered with the correct number of cells to deliver a stable 5V - 6V voltage. Perfect for directly charging USB devices or integrating with standard Lithium Battery Management Systems (BMS).

Sleek & Durable Integration

Features round corners and a seamless lamination design. Our panels are safe to handle on assembly lines and easy to integrate into consumer electronic products.

Request OEM Quote for IoT/Mini Panels

Fast response within 24 hours. Custom dimensions, voltage, and shape.

Direct Engineering Contact, OEM & custom solar panel projects

FAQ for OEM Small solar panels

Q1: Why do some mini panels turn yellow after a year?

A: This usually happens with Epoxy (Resin) panels because the resin reacts to UV light. If your product is for long-term outdoor use (like a garden light), we strongly recommend choosing our PET or ETFE series, which uses UV-stable lamination technology to prevent yellowing.

Q2: Do I need to pay a mold fee for custom sizes or shapes?

A: In most cases, NO. Unlike plastic injection parts, we use advanced Precision Laser Cutting technology for both the solar cells and the FR4 fiberglass backboard. This allows us to cut any shape (Round, Square, or Irregular) directly from your CAD drawing without expensive hardware molds. You typically only pay for the unit price.

Q3: Can you provide panels with pre-soldered wires and connectors?

A: Yes, absolutely. To speed up your assembly line, we offer full Integration Services. We can deliver panels with:

Custom Wire Length & Gauge: (e.g., 150mm red/black wires).

Connectors: JST (PH2.0, XH2.54), USB, or DC Jacks installed.

Blocking Diodes: To prevent battery backflow at night. Just let us know your spec, and your panels will arrive ready to plug and play.

Q4: Can Sola-E customize the shape and voltage for mini solar panels (0.1W - 20W)?

A: Absolutely. As a specialist mini solar panel factory, we understand that small-scale applications like IoT sensors and wearable electronics require precision. We can customize the dimensions, output voltage (from 0.5V to 18V+), and shape to fit your casing. We offer various encapsulation options, including ETFE, PET, and Epoxy resin, to balance durability and cost for your specific project needs.

Q5: What is the typical application for your 0.1-20W custom solar modules?

A: Our small wattage panels are widely used by global OEM clients for IoT tracking devices, marine environmental sensors, smart garden lights, and portable power banks. If you need a reliable small solar panel manufacturer in China for high-volume supply, Sola-E provides consistent quality with 100% EL testing even for the smallest cells.

Need a Custom Size? Check with Engineers

Whether you choose PET or ETFE, we customize the shape and voltage to fit your device perfectly.