Introduction

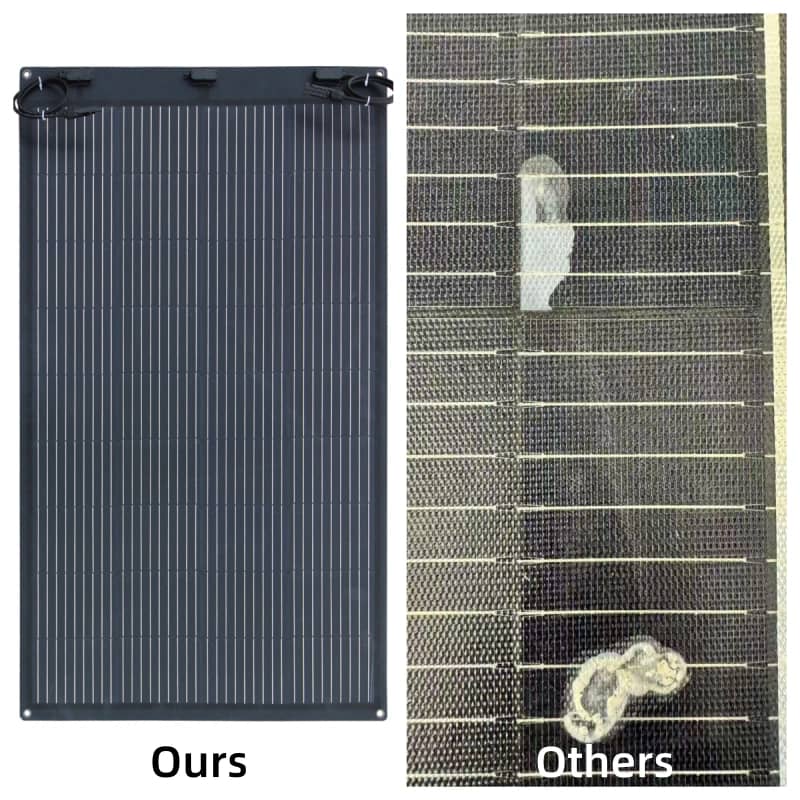

You’ve seen the photos—maybe you’ve even had to process the angry email from a client yourself. Picture a sleek catamaran in the marina, ruined by flexible solar panels that look like old, blistered skin. The formerly clear surface has turned a cloudy, sickly yellow, ruining the boat’s look and killing the power output.

For a procurement manager or marine engineer, this is an absolute nightmare.

In my experience sourcing marine electronics, the comparison of ETFE vs PET solar panels is the most critical decision you will make. The root cause is usually hidden in the Bill of Materials (BOM): PET. Standard plastic cannot handle the ocean. To guarantee durability, you need a composite structure engineered to withstand hydrolysis, salt mist, and thermal cycling.

Note for Australian & NZ Buyers: Due to the high UV index in the southern hemisphere, PET panels often fail within 12 months. We strongly recommend ETFE for all AU/NZ camping gear.

Who is this guide for?

This engineering analysis is specifically written for B2B decision-makers—OEM boat builders, marine distributors, and refit yards—who need to secure a reliable solar panels folding supply factory and cannot afford the reputational cost of product failure.

Table of Contents

Key Takeaways: The Engineering Brief

If you are sourcing for an OEM, here is your 30-second summary:

- The Lifespan Gap in ETFE vs PET solar panels: Standard PET panels typically degrade within 1–3 years. ETFE panels are built to last 15–25 years (up to 35 years in optimal conditions).

- Power Yield: Due to higher transmittance and lower degradation, ETFE generates 10–15% more power over its lifecycle compared to PET/PVDF.

- The “Stack” Matters: A durable panel requires a Fiberglass Core (tensile strength) and IBC Cells (structural integrity), not just an ETFE coating.

- Compliance is Mandatory: Demand IEC 61701 (Salt Mist) and check for Damp Heat Aging performance (<2% loss after 1000h).

Why ETFE is better: The Chemistry of Hydrolysis

To understand the longevity differences between ETFE vs PET solar panels, we must look at the chemistry.

1. The Moisture Barrier Failure

PET (Polyethylene Terephthalate) is excellent for water bottles but catastrophic for marine solar. The problem is molecular. PET has a poor barrier against moisture, with a Water Vapor Transmission Rate (WVTR) of >5g/m²·day.

This allows moisture to penetrate the panel daily. When combined with heat (>45°C), this triggers hydrolysis, literally breaking the chemical bonds of the plastic.

2. The Result: Yellowing & Cracking

As the bonds break, the plastic turns yellow, causing light transmittance to drop below 85%. Simultaneously, the material becomes brittle and crumbles like a dry rubber band.

3. The “Pothole Effect” (Salt Corrosion)

Once the PET cracks, salt mist settles inside. When the sun evaporates the water, salt crystals expand, acting like tiny wedges that push the layers apart (delamination). This exposes the internal wires to corrosion.

Don’t Risk Your Reputation with Cheap PET

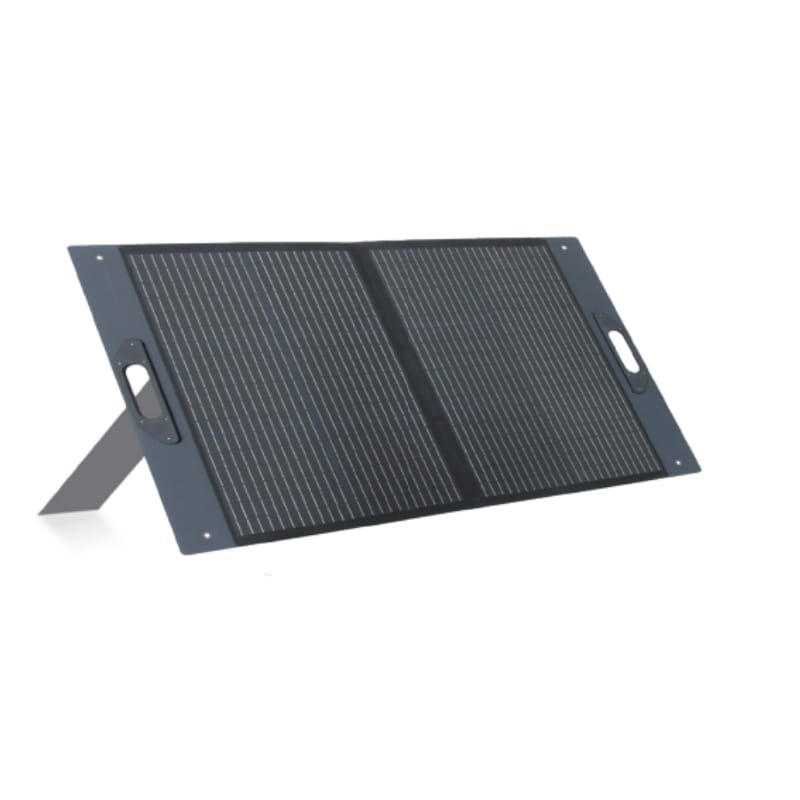

Our 30W Foldable Solar Charger uses the exact Marine-Grade ETFE described above. It’s tested to survive 85°C heat—perfect for the Australian Outback and Marine environments.

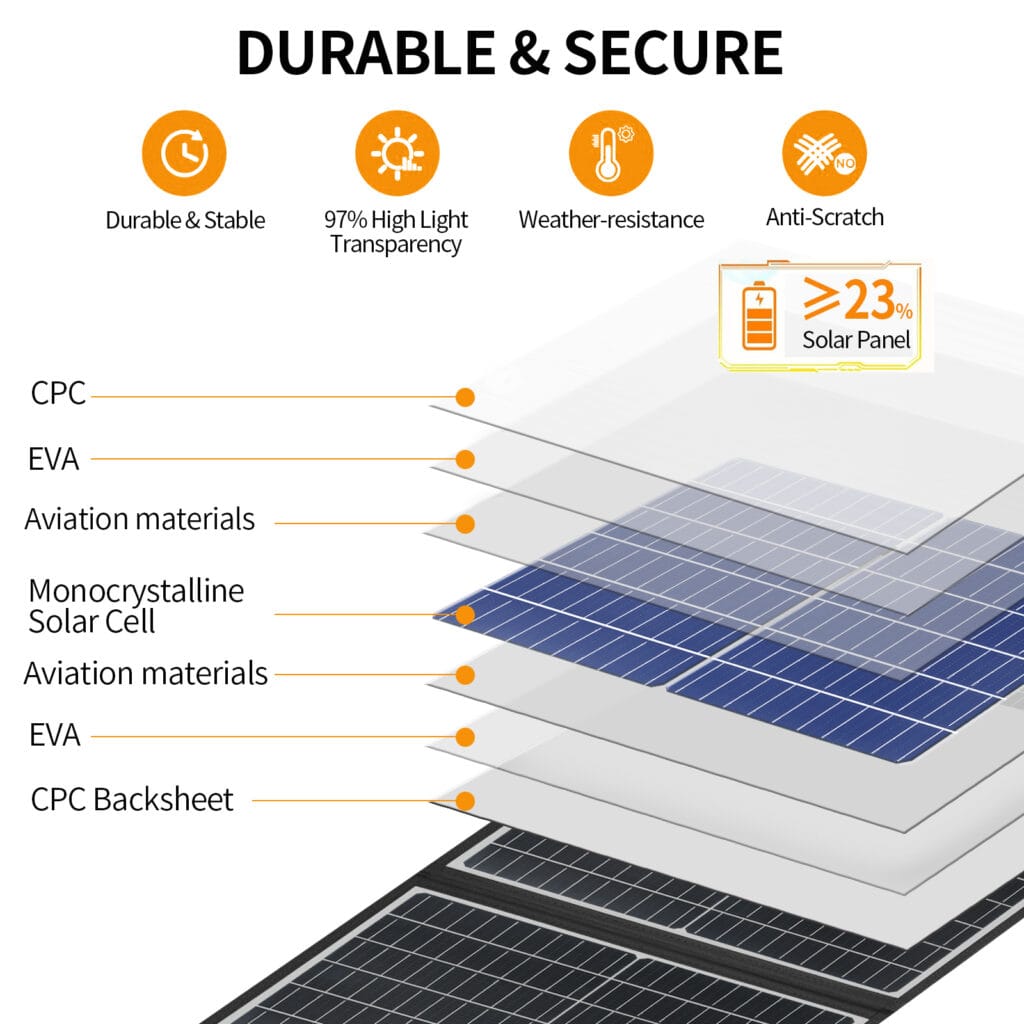

The Solution: The Marine-Grade Stack

We cannot simply change the wrapper; we have to re-engineer the entire internal structure. We call this solution the “Layer Cake”.

Exploded view of a solar panel detailing the layered construction from the protective outer frame to the core photovoltaic cells.

1. The Shield: ETFE (Not PVDF)

We use a fluorine-based polymer (ETFE) rather than PET or PVDF.

- Why not PVDF? While better than PET, PVDF only has ~85% light transmittance. More importantly, it has lower fluorine content than ETFE, making it prone to micro-layer separation (delamination) over time.

- The ETFE Advantage: It offers 90–95% light transmittance (approaching glass) and uniform light spectrum transmission. Its film thickness (0.025–0.25mm) keeps the total component weight under 1kg/m²—just 1/10th the weight of glass.

2. The Core: Fiberglass Reinforcement

ETFE has high tensile strength (40–50MPa) and elongation (300–400%). However, silicon cells are brittle. We sandwich a semi-rigid fiberglass layer in the middle to match ETFE’s flexibility with structural support, preventing the “floppy” effect.

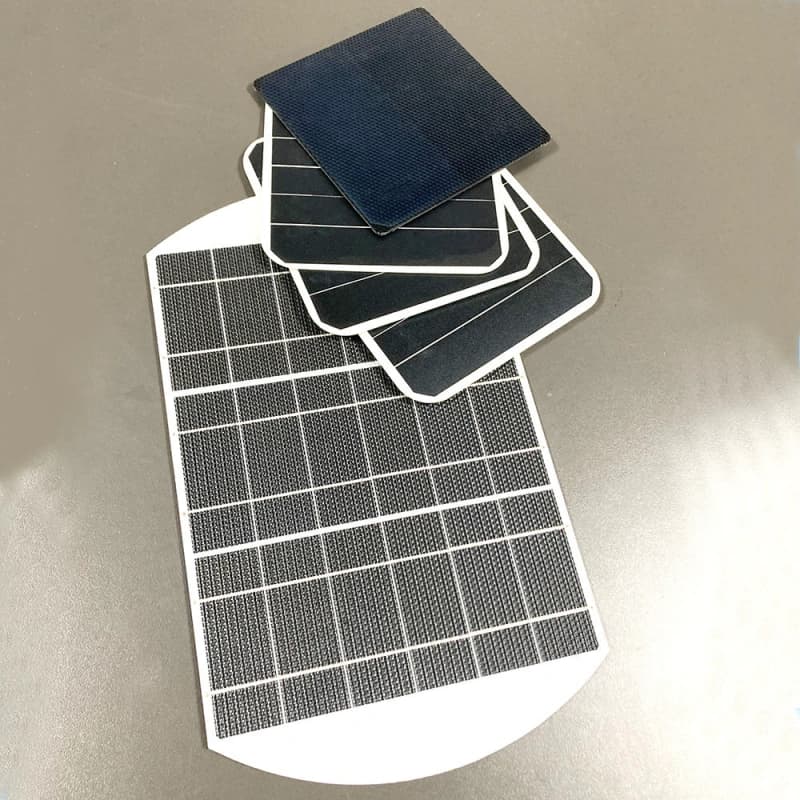

3. The Engine: IBC Cells

Standard cells use front busbars (thin silver paste) that snap under tension. We use IBC (Interdigitated Back Contact) cells, which feature a solid copper foundation on the rear, acting as a structural backbone.

4. The Foundation: TPT Backsheet

We use a Tedlar-Polyester-Tedlar (TPT) backsheet to block moisture ingress from the deck side, ensuring the “floor” of the panel doesn’t rot out.

Material Science: ETFE vs PET Solar Panels Explained

We don’t just rely on field anecdotes; we look at the lab data comparing materials under accelerated aging (85℃ / 85% Humidity).

Lab Data: Damp Heat Aging Test (1000 Hours)

| Material Type | Power Attenuation (1000h) | Result |

| Standard PET | > 4.89% | Failed. Significant hydrolysis and yellowing. |

| PVDF Composite | ~ 3.5% | Warning. Risk of interlayer separation. |

| Marine ETFE | 1.98% | Pass. Minimal degradation. |

The Conclusion: While PET saves money upfront, ETFE delivers superior long-term stability, ensuring your power system survives the harsh marine environment.

Marine Solar Installation Tips: Managing Heat

A common cause of failure is thermal over-stress. Gluing a black panel directly to a white fiberglass deck creates a heat trap, literally cooking the cells.

- Recommendation: Maintain a tiny layer of airflow underneath the panel.

- Solution: Mount panels on Twin-Wall Polycarbonate sheets. The hollow channels act like cooling tunnels, reducing operating temperatures by 10–15 °C.

Glossary of Terms

Here are simple definitions for the technical terms used in this guide.

- Delamination: When the layers of a solar panel peel apart (like an old sticker lifting at the edges), usually caused by moisture or heat.

- Hydrolysis: A chemical reaction where water breaks down plastic. This is the main reason PET panels turn yellow and crack.

- IBC (Interdigitated Back Contact): A premium type of solar cell that uses a solid copper backing instead of thin silver wires, making it much stronger.

- IEC 61701: The international standard test for Salt Mist Corrosion. If a panel passes this, it is proven to survive ocean environments.

- WVTR (Water Vapor Transmission Rate): A measure of how much moisture passes through a material. Lower is better.

2025 Sourcing Checklist

Use this checklist during your next supplier audit to ensure compliance.

- Mechanical: Is there a fiberglass reinforcement layer? (Avoid 3-layer PET-Cell-PET panels).

- Material Check: Is the top layer ETFE or PVDF? (ETFE has higher transmittance: 90-95%).

- Validation: Do you have the IEC 61701 salt mist report?

- Protection: Is the junction box IP67/IP68 and fully potted with resin?

FAQ (Technical & Sourcing)

Q: Why choose ETFE over PVDF? They are both fluoropolymers, right?

A: Correct, but ETFE is superior for solar. PVDF typically has lower light transmittance (85-90%) compared to ETFE (90-95%). More importantly, lab analysis shows that PVDF is more prone to micro-cracking and delamination after long-term UV exposure compared to the cross-linked structure of ETFE.

Q: What is the maintenance advantage of ETFE?

A: ETFE is chemically “inert” and non-stick. In many cases, it reduces cleaning maintenance costs by over 50%. Rainwater tends to bead up and wash away dirt and salt (self-cleaning), whereas PET and glass tend to accumulate grime that requires manual scrubbing.

Q: What is the cost difference between PET and ETFE solar panels?

A: An ETFE panel typically costs 30% more upfront than a PET version. However, PET panels often fail within 1-3 years. The total cost of ownership for ETFE is significantly lower over a 5-year period due to avoided replacement labor.

Q: Can I walk on ETFE solar panels?

A: Yes, but only if they are mounted flush on a rigid surface with no gaps underneath. You must wear soft-soled deck shoes or go barefoot; never walk on them if they are installed on canvas or uneven surfaces.

Q: How long do ETFE solar panels last?

A: High-quality ETFE panels from Sola-E can last 5-7 years outdoors without yellowing, whereas PET panels typically degrade within 1-2 years.

Q: Is ETFE more expensive than PET?

A: Yes, ETFE materials cost about 20-30% more than PET, but they offer 3x the lifespan, making them cheaper in the long run for B2B brands.

Q: Can ETFE panels be used on yachts?

A: Absolutely. ETFE is corrosion-resistant and withstands salt spray, making it the industry standard for marine solar applications.

Conclusion: The ROI of Quality

If you take only one thing away from this guide, let it be this: In the marine industry, the cheapest option is usually the most expensive one.

Think about the cost of your reputation. Think about the cost of a technician spending four hours scraping melted glue off a deck.

ETFE isn’t just a “premium upgrade.” With a 1.98% degradation rate after extreme aging tests versus PET’s >4% failure, it is the baseline for professional marine energy.

Don’t let a piece of plastic be the weak link in your product line. Build it right, build it once.

As a professional folding solar panel factory, we apply these tests to every batch. → View our production process

Want to see the difference yourself?

We offer a Discounted Sample Program for B2B buyers. Order a 30W ETFE Demo Unit today to test its charging speed and durability before bulk ordering.