The core contradiction of portable solar is simple:

Customers treat it like a towel, but it is made of silicon.

Outdoor enthusiasts stuff portable panels into backpacks, sit on them, lay them over rocks, and fold them thousands of times.

Standard portable solar panels use rigid silicon wafers. If you bend a rigid wafer, it breaks. If you fold a copper wire repeatedly, it snaps.

Yet, buyers demand smaller, lighter, and more foldable products.

At Sola-E, we view “Handling Risk” as an engineering problem. We don’t just hope the user is gentle; we design for The Unpredictable Outdoor User.

Risk 1: The “Origami” Effect (Folding Hinge Failure)

The Threat:

The weakest point of any foldable charger is the hinge.

Cheap panels use the encapsulant itself (PET plastic) as the hinge. After 50-100 folding cycles, the PET fatigues, turns white, and cracks, exposing the delicate wiring between panels to moisture and oxidation.

The Consequence:

One day, the panel just stops working. The internal “busbar” (the wire connecting the fold) snaps due to metal fatigue.

How We Manage It:

We use Reinforced Fabric Integration.

Instead of relying on plastic hinges, we integrate the solar laminates into a high-denier, UV-resistant fabric base.

10,000 Cycle Test: Our hinges are tested to withstand thousands of open-close cycles without electrical failure.

Strain Relief: The wiring between panels is looped with specific slack to ensure that bending the panel never pulls the wire taut.

Risk 2: The “Backpack” Problem (Compression & Impact)

The Threat:

Hikers and soldiers don’t carry panels in hard cases; they shove them into soft backpacks.

When the pack is dropped on the ground, or when someone leans against a tree, the panel inside experiences point-loading compression.

Standard PET panels are thin. A single sharp object (like a water bottle cap or a rock) pressing against the panel can shatter the cells inside.

How We Manage It:

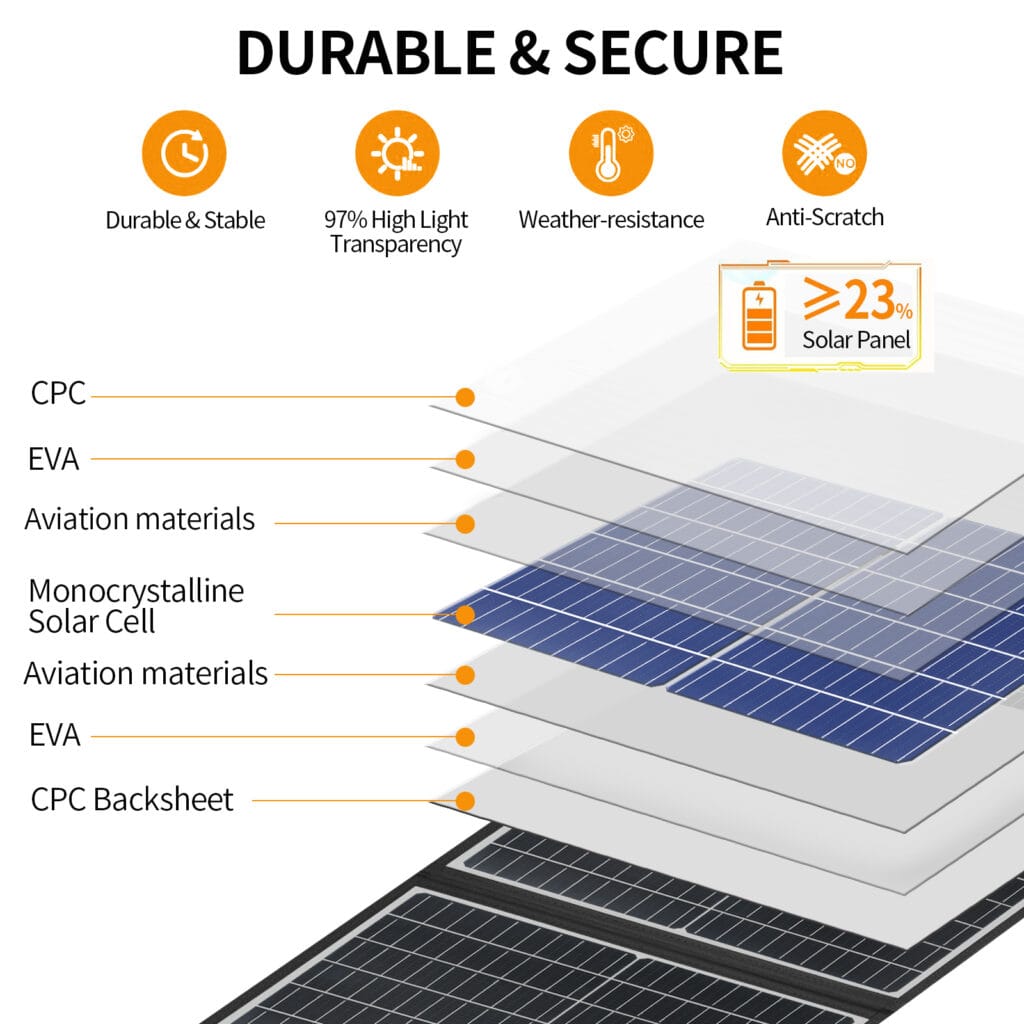

We use a Composite Armor strategy.

- ETFE Surface: Unlike PET (which scratches and dents easily), our ETFE surface is self-healing and tougher against abrasion.

- PCB/FR4 Backing: For our premium lines, we bond the solar cells to a stiff fiberglass (FR4) backing sheet before lamination. This acts as a shield. Even if the user sits on their backpack, the load is distributed across the fiberglass plate, preventing the brittle cells from cracking.

Risk 3: The “Uneven Ground” Trap (Step-On Risk)

The Threat:

In the field, the ground is never flat. Panels are laid over sticks, stones, and tufts of grass.

If a user accidentally steps on a panel bridging a gap between two rocks, the cell will flex beyond its limit and snap instantly.

The Solution:

We engineer for Micro-Flexibility.

- Shingled Cell Technology: We use shingled or multi-busbar (MBB) cells that have higher tolerance for micro-cracks. Even if the dense wiring matrix keeps the current flowing.

- Thicker Encapsulant: We use a thicker layer of EVA/POE adhesive. This acts as a “cushion,” allowing the cell to slightly deform over a rock without immediately shattering.

Note: While our panels are tougher, we still advise users to treat them as precision instruments. See our guide on mobile solar failure risks for more on vibration damage.

The Commercial Reality: Returns Kill Margins

For outdoor brands, a “cheap” solar panel is the most expensive product you can sell.

Why? Returns.

In fact, many returns are classified as “DOA” (Dead on Arrival) simply because micro-cracks occurred during shipping or the customer’s first unboxing handling. If a customer hikes for 3 days and their charger dies on day 2, they don’t just return the product—they write a 1-star review that kills your listing.

Sola-E’s portable series is designed to survive the trip, the drop, and the fold.

Don’t sell a disposable toy. Sell reliable gear.

Build Gear That Lasts

Are you sourcing for outdoor retail, military, or disaster relief? Stop risking your brand on fragile panels. Get our Durability Test Report today.

FAQ: Handling Portable Solar

Q1: Can I fold the solar panel in any direction?

A: No. Only fold along the designated fabric hinges. Folding the panel section itself (bending the hard part) will crack the silicon cells instantly. Always follow the natural fold lines.

Q2: Is ETFE better than PET for portable panels?

A: Yes, significantly. PET is cheaper but degrades under UV light (turns yellow/brittle) and scratches easily. ETFE is a fluoropolymer that is UV-transparent, self-cleaning, and much more resistant to the abrasion of being stuffed in and out of bags.

Q3: Can I leave my portable panel in the rain?

A: The panel face is waterproof (IP65/IP67), but the USB/DC junction box is usually the weak point. Unless specified as waterproof, always keep the output ports dry or covered.