Why Portable Solar Panels Fail: User Error vs Product Defects (Top 10 Causes)

For any distributor of portable power products, the “Defective Item” return request is a daily reality. However, our internal data suggests that over 60% of returned panels are fully functional.

The issue is rarely the hardware; it is the application.

Portable and flexible solar panels are robust, but they operate under strict physical rules. When users treat them like rugs or wall sockets, performance suffers. This guide outlines the Top 10 Common Misuses—divided by product type—to help our partners troubleshoot issues before authorizing a return.

Table of Contents

The Foldable 5: Mistakes with Portable Chargers

Users of foldable solar panels often prioritize convenience over placement, leading to these five common performance killers.

1. The “Partial Shade” Misunderstanding

The Scenario: A user places the panel under a tree, where 90% is in the sun but one corner is covered by leaf shadows. Output drops to near zero.

The Physics: Unlike residential roof panels which have multiple Bypass Diodes to route current around shading, portable panels often have limited diode configurations to save space. Blocking just one cell can force the entire circuit to shut down to protect itself.

The Fix: Educate users that 100% direct sunlight is required. Even a small shadow matters.

2. Charging Behind Glass

The Scenario: A user puts the panel on the dashboard inside a car or behind a balcony window to prevent theft.

The Physics: Modern windows have UV and IR coatings designed to block heat and radiation—the exact energy solar panels need. Output can drop by 50-70%.

The Fix: Panels must be placed outside, with no glass barrier.

3. Cable Dragging (The “Yank”)

The Scenario: To pack up quickly, the user pulls the panel by the cable instead of the handle.

The Physics: While the junction box is glued and screwed, the internal solder joints are delicate. Repeated yanking creates micro-disconnections inside the box.

The Fix: Always grip the connector head, never the wire, when unplugging.

4. The “Hot Pavement” Effect

The Scenario: Placing the panel flat on hot asphalt or concrete in summer.

The Physics: Solar panels lose efficiency as they get hot (known as the temperature coefficient. Placing them on a heat-radiating surface without airflow underneath cooks the cells, temporarily reducing voltage and risking fabric delamination over time.

The Fix: Always use the kickstands to create an air gap for cooling.

5. Water Resistance vs. Salt Corrosion

The Scenario: Assuming “Waterproof IP67” means the panel needs no maintenance in marine environments.

The Physics: While the panel is sealed, the metal connectors (USB/MC4) are vulnerable to salt spray. Salt crystals build up inside the plugs, causing corrosion and poor contact within weeks.

The Fix: Connectors must be kept dry. If used near the ocean, clean ports with fresh water and apply dielectric grease if recommended.

The Flexible 5: Mistakes with Installation

Flexible solar panels face a different set of risks because they are often installed semi-permanently on boats or RVs.

6.The “Invisible Defect” (Generic Quality Risk)

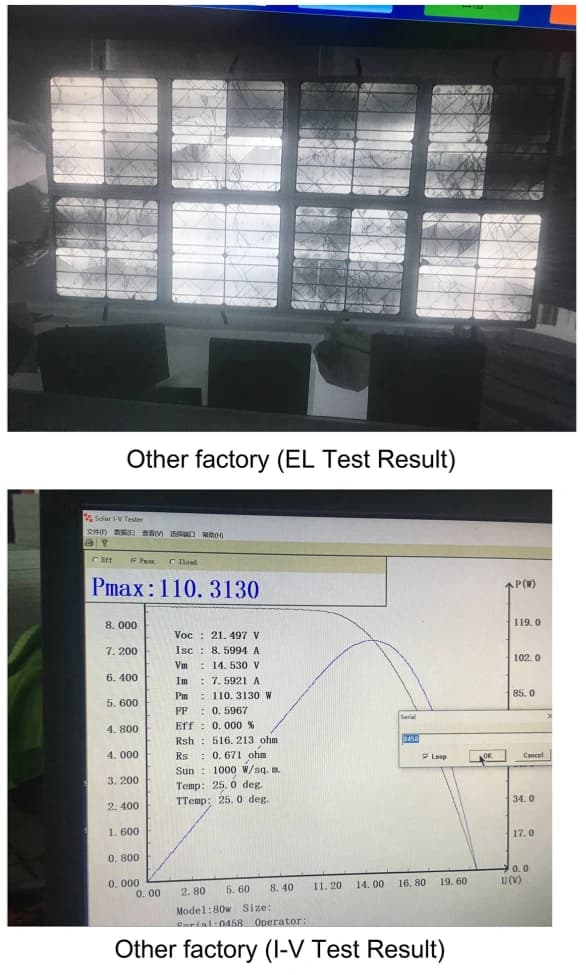

The Scenario: A partner performs an EL (Electroluminescence) test on a batch of flexible panels sourced from a standard factory. While the panels look visually perfect, the EL image reveals dark “spiderweb” cracks across the cells.

The Physics: Most generic flexible panels lack internal structural reinforcement. They often develop immediate micro-cracks during basic manufacturing handling or shipping vibration before they even reach the customer. Unlike our reinforced matrix, standard panels are often “Dead on Arrival” internally.

The Fix: Never rely on visual inspection alone. Generic panels often hide structural failures that only EL testing can reveal.

7. Over-Bending

The Scenario: Trying to wrap the panel around a sharp corner or folding it like a sheet of paper.

The Physics: Most flexible panels have a bending limit (usually 30 degrees). Exceeding this snaps the internal cell connections (busbars or cell edges).

The Fix: Respect the Minimum Bending Radius specified in the datasheet.

8. Canvas Flapping (The Marine Killer)

The Scenario: Mounting a panel on a Bimini top (canvas roof) that is loose.

The Physics: As the boat moves, the wind whips the canvas up and down. This thousands-of-times-per-hour vibration causes metal fatigue in the solar cells, leading to failure within months.

The Fix: The mounting surface must be tensioned and rigid. If installing on canvas, use support bars to stop the flapping.

9. Chemical Incompatibility

The Scenario: Using a random construction adhesive to glue the panel down.

The Physics: Some aggressive adhesives react chemically with the panel’s plastic backsheet, eating through the insulation layer and causing corrosion or bubbles.

The Fix: Only use neutral-cure silicone or recommended structural adhesives (like Sikaflex).

10. Hot Spotting via Permanent Shade

The Scenario: Installing the panel right next to a mast or radar arch that casts a shadow on the same spot every day.

The Physics: The shaded cells act as resistors, heating up as the rest of the panel tries to push current through them. Over time, this focused heat burns the panel permanently.

The Fix: Plan the layout to avoid permanent obstacles.

Strategy for Partners: How to Use This Guide

We don’t just list these problems; we help you prevent them. Sola-E partners are encouraged to:

- Update User Manuals: Add a “Do’s and Don’ts” visual guide based on these 10 points.

- Train Support Teams: When a customer claims “Low Power,” ask for a photo of the setup first. 8 out of 10 times, you will spot one of the errors above.

- Define Warranty Terms: Clearly exclude damages caused by improper installation (like point impact or chemical corrosion) to protect your margins.

Looking for More Resilient Solar Solutions?

While we can’t stop every user error, we can engineer panels that are more forgiving. From Shingled Cells that resist micro-cracking to ETFE coatings that handle heat better, we design for reality. Access our full library of risk control and partner resources here:

FAQ: Troubleshooting Solar Panel Failures

Q1: Can I put my solar panel behind a window?

A: No. Most modern windows have UV-blocking coatings that reduce solar panel efficiency by 50% or more. Always place panels in direct, outdoor sunlight.

Q2: Can I walk on flexible solar panels?

A: Generally, No. Unless the panel is fully glued to a rigid deck and explicitly rated as “walkable” by the manufacturer, walking on it will cause micro-cracks and void the warranty.

Q3: Why does a small shadow kill the entire power output?

A: Portable panels often have limited bypass diodes to save space. Blocking just one cell can force the entire series circuit to shut down to protect the system.

Q4: Is it safe to mount flexible panels on a canvas Bimini?

A: Yes, but only if the canvas is tight. If the canvas flaps in the wind, the constant vibration will fatigue the solar cells and cause failure. You may need to add support bars.