Flexible solar panels are increasingly popular for RVs, vans, and marine vessels — but they also fail more frequently in these applications than in residential rooftop systems.

The reason is rarely just “bad manufacturing.”

It is usually misapplication.

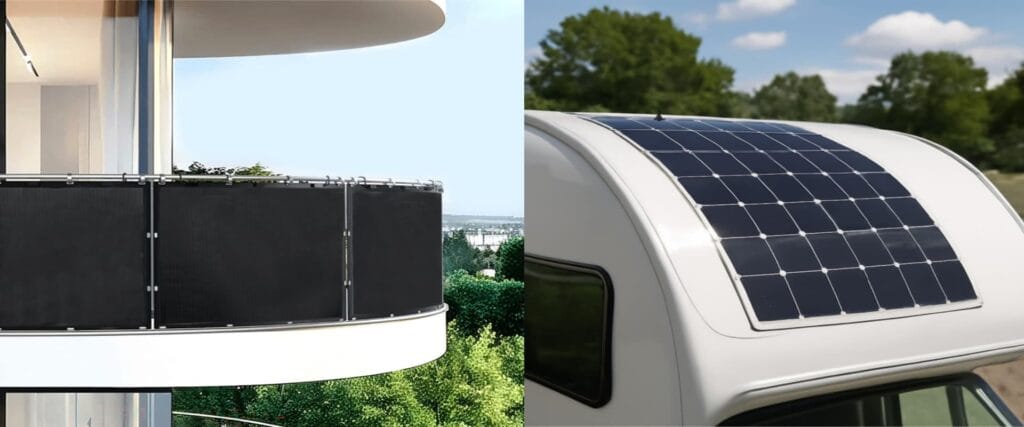

In RV and marine environments, a solar panel is no longer a passive energy device. It becomes a vehicle component, exposed to hurricane-force winds (highway speeds), constant vibration, salt mist, and trapped heat.

Most flexible solar panels on the market are originally designed for static, temporary use. When they are glued onto insulated RV roofs or boat decks without considering thermal dissipation or surface mechanics, premature failure is inevitable.

This article breaks down why panels fail and how professional manufacturers manage these risks through engineering protocols that go far beyond the spec sheet.

RV & Marine Solar Is Not Residential Solar

In a residential installation, a solar panel sits on a stationary roof, tilted at a perfect angle, untouched for 25 years.

In mobile applications, that same panel acts as a shield.

It must survive constant earthquake-like vibration (potholes) and corrosive salt baths. Yet, many buyers still use standard procurement criteria for these extreme environments. This is a costly mistake.

At Sola-E, as a specialized solar panel manufacturer, we don’t just sell products; we manage application risk. Here is how we engineer out the three most common causes of mobile solar failure.

Risk 1: Physical Stress — Vibration & Foot Traffic

The Threat:

Every mile you drive sends shockwaves through your solar array. On a boat, deck space is premium, and panels are often walked on.

The Symptom:

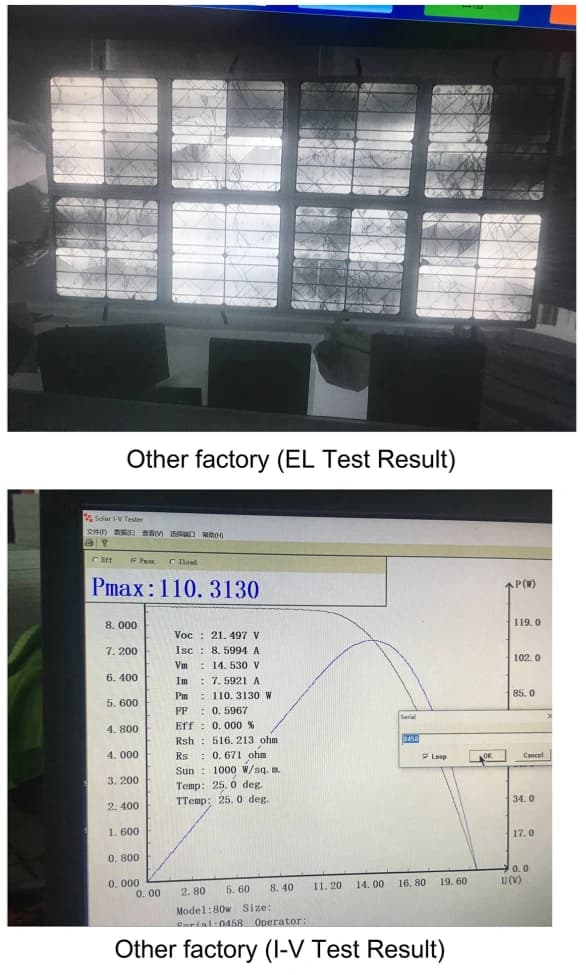

Standard silicon cells are brittle. Under constant road vibration or the pressure of a shoe, they develop micro-cracks—invisible fractures that sever electrical pathways.

The panel looks perfect from the outside, but the amperage drops to near zero.

How We Manage It:

We don’t rely on luck. We validate our designs against IEC 62759-1 (Transportation Vibration) standards.

- Cell Protection: We use higher-grade, multi-busbar cells that maintain connectivity even if micro-cracks occur.

- Walkable Design: For marine decks, we recommend our marine grade solar panels with reinforced backsheets. When installed flush on a rigid surface, the textured ETFE surface distributes foot pressure, allowing for occasional walking without damaging the cells underneath.

Risk 2: Corrosion — Salt Mist Risk in Marine Solar

The Threat:

Salt mist is pervasive. It doesn’t just rust metal; it penetrates the backsheet and delaminates the encapsulation layers.

The “Void” Trap:

Many standard solar warranties explicitly exclude damage from “salt water or marine environments.” If you buy a standard panel for a boat, you often have zero warranty the moment it leaves the dock.

How We Manage It:

IEC 61701:2020 describes salt mist corrosion testing sequences for photovoltaic modules and can be used to evaluate corrosion resistance in marine environments.

- Material Selection: We replace standard frames with anodized aluminum (thicker oxide layer) and use ETFE polymers instead of PET. ETFE is chemically inert to salt spray, whereas PET yellows and cracks over time.

- Waterproof Integrity: We use IP67/IP68 rated junction boxes filled with potting compound to prevent moisture ingress.

Risk 3: Thermal Runaway — Overheating on RV Roofs

The Threat:

Heat is the #1 enemy of efficiency and lifespan. As detailed in our guide on solar panel real-world output, high temperatures significantly reduce power generation.

Flexible panels glued directly to highly insulated surfaces (like TPO or EPDM RV roofs) have nowhere to dump their heat.

The Consequence:

Without airflow, cell temperatures can exceed 85°C (185°F). This degrades the adhesive and causes thermal runaway, potentially burning the roof membrane.

How We Manage It:

We provide installation protocols that match the surface material.

- Metal Surfaces: Direct gluing is acceptable. The vehicle’s metal body acts as a giant heat sink.

- Insulated Surfaces: We recommend the “Air Gap” Strategy. Installing the panel on a twin-wall polycarbonate sheet (corrugated plastic) creates a 4mm passive air channel. This simple spacer can lower operating temperatures by 15-20°C.

For more details on where not to install these panels, refer to our article on application boundaries and limitations.

The Commercial Reality: Why “Marine Grade” Costs More

Managing these risks requires expensive materials (ETFE, Potting Compound) and rigorous testing.

- A $80 “camping panel” is designed for a weekend trip.

- A Sola-E Marine Module is designed for a 10-year service life in hostile environments.

Don’t let your brand reputation die on a highway or in the middle of the ocean.

Partner with a manufacturer who understands the physics of failure. Contact our engineering team today to discuss your OEM requirements.

Are Your Rigs Ready for the Real World?

Don’t risk your brand reputation on untested solar components. Our engineering team offers free application validation for qualified OEM partners.

FAQ for flexible solar panels

Q1: Can I walk on marine flexible solar panels?

A: Yes, but with strict conditions. High-quality marine panels using ETFE surfaces and reinforced backsheets can withstand foot traffic, provided they are installed on a 100% rigid surface (no gaps underneath) and you wear soft-soled deck shoes.

Q2: Do flexible solar panels overheat on RV roofs?

A: They can if installed incorrectly. Gluing them directly to an insulated roof blocks heat dissipation. We recommend installing them on twin-wall polycarbonate sheets to create a passive air gap.

Q3: What is “Marine Grade” solar?

A: True “Marine Grade” refers to specific durability standards. It requires compliance with IEC 61701 (Salt Mist), waterproof junction boxes (IP67+), and corrosion-resistant materials like ETFE. Standard panels often fail within 1-3 years in saltwater.