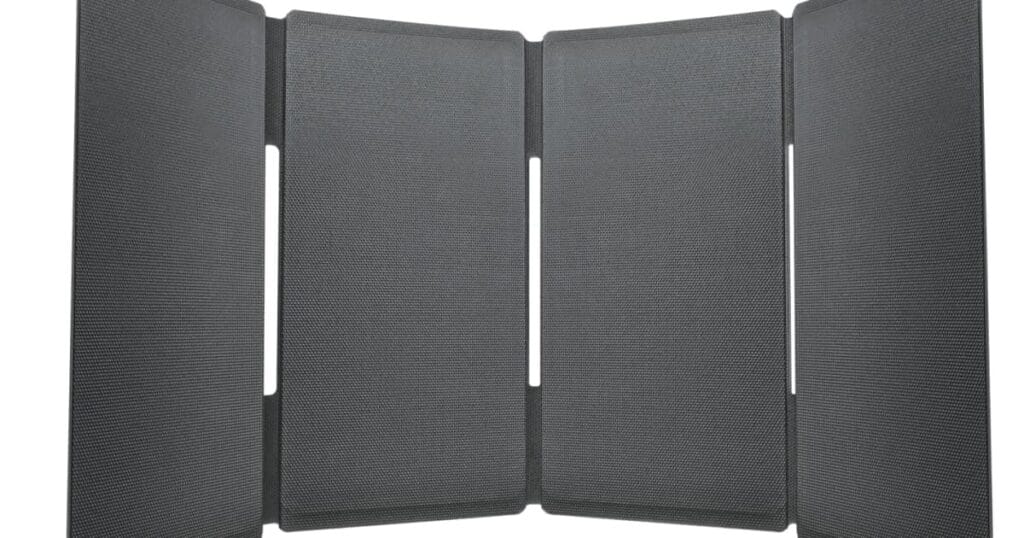

Foldable solar panels are designed to move.

They are folded, unfolded, transported, stacked, repositioned, and often handled by non-professional users.

From a product perspective, this mobility is a feature. From a channel perspective, it is also the primary source of risk.

Where Risk Actually Comes From

In real-world use, foldable solar panels are exposed to repeated mechanical stress, including:

- Frequent folding and unfolding

- Transportation pressure during storage or travel

- Minor drops or impacts

- Uneven ground placement

None of these behaviors are extreme or improper. They are simply part of how portable products are used.

The challenge is that structural stress accumulates over time, and its impact is not always immediately visible.

The Problem with Delayed Performance Issues

One of the most difficult situations for distributors and retail channels occurs when:

- The panel appears physically intact

- Initial performance is normal

- Output gradually declines weeks or months later

In these cases, it becomes difficult to determine whether the issue originated from usage, handling, or internal structural fatigue.

This type of delayed performance behavior is far more damaging to channel confidence than immediate, visible damage.

Design Approach: Controlling Stress During Movement

Our foldable solar panels are engineered with a focus on controlled bending behavior, rather than assuming ideal handling conditions.

Key design considerations include:

- Reducing stress concentration during folding

- Allowing predictable bending paths

- Improving tolerance to everyday handling and transportation

The goal is not to eliminate all mechanical stress — which is unrealistic — but to prevent stress from turning into hidden structural damage that later affects performance.

Why This Matters for Channel Partners

For distributors and retailers, foldable panels must remain explainable throughout their service life.

By reducing the likelihood of hidden structural issues caused by normal movement, this design approach helps support:

- Fewer delayed after-sales disputes

- Clearer communication with end users

- More predictable product behavior over time

In portable products, reliability is not only about durability — it is about avoiding failures that are difficult to explain or verify.

Designed for Predictable Use, Not Ideal Conditions

Foldable solar panels are not laboratory products. They are used in motion, by real people, in real environments.

Our focus is to ensure that repeated handling does not become an uncontrolled variable — but remains within a predictable and manageable risk range for channel partners.

FAQ(Frequently Asked questions)

Q1: Does “controlled bending” mean the panel cannot be damaged by folding?

Answer: No portable panel is indestructible. “Controlled bending” means we design the hinge and circuit layout to minimize stress accumulation during normal operation. Our goal is to ensure that standard usage (opening, closing, packing) does not degrade output over time, distinct from accidental abuse or extreme impact.

Q2: How do you define “normal handling” for warranty purposes?

Answer: This is a common gray area in the industry. We work with our partners to define clear usage boundaries based on our stress-test data (e.g., folding angles and frequency). We prefer to define these limits in the technical agreement before the order, rather than arguing about “misuse” after a claim arises.

Q3: Do you test the folding mechanism in-house?

Answer: Yes. We conduct cycle testing on both the fabric/hinge structure and the electrical continuity of the cells under repeated motion. Partners are welcome to review our specific testing protocols for foldable products.

Looking for a Reliable OEM Partner?

Understanding these risks is the first step. Preventing them requires a manufacturing partner who designs for reality, not just for the spec sheet. We have documented our complete approach to risk control, warranty boundaries, and partner support here: